Production Management is a process which involves managing and controlling production activities of the business. It involves the application of management principles to the production function of the business to increase productivity. Production management applies planning, directing, organising and controlling for managing production operations. This process is concerned with the conversion of raw materials into business finished products efficiently without any wastage of resources.

Contents

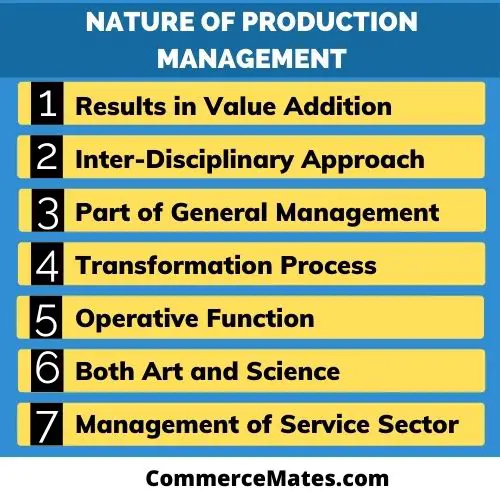

Nature of Production Management

- Results in Value Addition: Production management is a key tool available with an organization which assist in value addition. It is a process which enables in producing high-quality products by purchasing raw materials from the right source, in right form, at right price and in right quantity. These quality goods provide better satisfaction to customers thereby improving goodwill of an organization.

- Inter-Disciplinary Approach: It is an inter-disciplinary approach which is derived from several disciplines and subjects. Different subjects like statistics, mathematics, economics, engineering, sociology and human psychology have contributed toward the development of production management approach.

- Part of General Management: Production management is an essential component of General management. It is a tool which assist managers in planning, organizing, coordinating and controlling all activities related to the production of products and services.

- Transformation Process: It is a process of transformation in which raw materials are converted into finished products that are ready for consumption by consumers. Production management focuses on economical production of products avoiding any wastage of raw materials used.

- Operative Function: Production management monitors day to day operations of business for ensuring long-term continuity. It supervises all production activities on daily basis for checking out whether all resources are efficiently utilized.

- Both Art and Science: It can be treated both as an art as well as science. Production management is termed as art as it is the one which assign, coordinates and monitors all work activities of an organization. Whereas, it is a science as it manages all machines and technical aspects helping in production activities.

- Management of Service Sector: Production management not only manages the activities related to production of tangible products. It is a process which monitors the service sector also where intangible products are provided to customers as per their needs.

Scope of Production Management

- Facility location: It involves selecting the right location for setting up production facilities of business that affects its long term growth. This is an important decision to be taken as it involves long term commitment and huge investments in land, building and machinery. Location of facility should be appropriate from where raw materials, labor and other factors of production are easily accessible by business.

- Plant layout and Material Handling: Plant layout is concerned with physical arrangement of facilities set up by business. It involves deciding departments, work Centre’s, machines and necessary equipment’s within the facility for ensuring better productivity. Material handling refers to managing the movement of materials from storeroom to machinery and from machinery to another stage of production like packaging and storing.

- Product Designing: Product designing means giving shapes to ideas of products for converting them into a reality. Every organization should come up with innovative products in market after conceiving new ideas based on market requirements.

- Designing of Process: Process design is an overall route followed by business for transforming raw materials into finished products. It is a crucial decision to be taken as it determines the efficiency of business. It involves choosing appropriate technology, deciding sequence of production processes and facilities layout.

- Production Planning and Control (PPC): It involves planning and controlling various aspects of production activities. PPC is a process of deciding production in advance, setting up the exact route for each item, deciding the start and finish deadline of each product for directing production orders to shops and following product progress in accordance with the order.

- Quality Control: Quality control is a process of checking and maintaining the required quality standards of production activities within the organization. It ensures that goods produced are of high quality by setting up check points and measuring performance from time to time.

- Maintaince Management: It refers to evaluation of all business activities for identifying any deviations if there. Maintaince management involves taking all corrective steps for removing these deviations. It focuses on keeping all the processes on track in line with decided quality, pre-determined cost schedule and time range. Taking care of all machinery repairs, replacement and servicing are included in this.