Contents

What is Production Management System?

Production management means planning, organizing, directing, and controlling of production activities of products or services, this whole process of managing production is called the Production Management System.

Production management helps the organization to convert raw material into finished goods in proper time. Production management deals in decision making, so that result of goods and services can be achieved in a quantitative way. Production Management is a set of general principles for production.

Production Management Definition

According to Elwood Spencer Buffa,

“Production management deals with decision-making related to production processes so that the resulting goods or service is produced according to specification, in the amount and by the schedule demanded and at minimum cost.”

Importance of Production Management

Reduces cost of production

The foremost benefit provided by production management is that it enables the business in minimizing its production cost. It monitors all production activities and ensures that proper efficiency is maintained at all times. Process of production management minimizes the inputs and maximizes the output level that leads to overall reduction of prices.

Enables in introducing new products

Production management technique plays an efficient role in bringing innovative products to the market. It facilitates conducting research and development in an organization resulting in newer and quality products. Such goods are easily accepted in the market as they offer better satisfaction to customers due to their superior quality.

Assist in facing competition

It is a very efficient tool available with management for tackling the stiff competition in market. The production management technique makes it possible for a company to provide quality products at the right price, in right quantity, and at right time. All this enables in attracting large customers easily and providing them better satisfaction via offering quality products.

Achievement of firm’s objectives

Production management assist business organizations in attaining their desired set of targets. It ensures that products are produced as per the customer requirements after doing a proper analysis. This leads to satisfy customers wants in more effective way. Therefore, in this way overall sales of firm will raise that will help in achieving objectives.

Firm expansion

Production management enables companies in expanding their operations over time. It serves as an efficient means of enhancing the overall quality of products and bringing down their cost. Companies are able to earn higher profit margins by enjoying better efficiency rates. These profits enable firm to the expansion of their operations and growing their size.

Fuller utilization of resources

Optimum utilization of all resources is must for every organization to earn desired returns. Production management monitors the usage of all resources within the organization and ensure that there is a minimum wastage. When all resources including material, machinery and manpower are optimally used then the firm can easily meet its objective of capacity utilization.

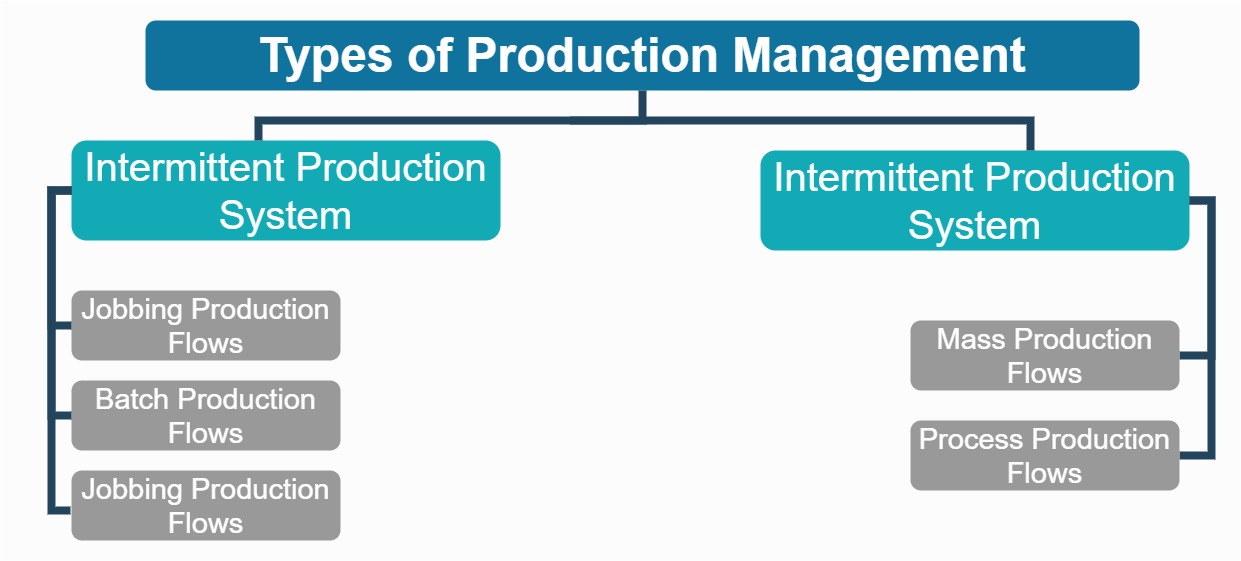

Types of Production Management

The types of Production Management system are grouped into two categories: –

- Intermittent Production System

- Continuous Production System

Intermittent Production system

It is a production system in which starts and stops at an irregular interval without having a fixed time interval. Goods are manufactured in accordance with customer orders on a small scale under the intermittent production system. Here, the flow of production is not continuous but irregular that varies as per the customer demands.

It is a very flexible production system where a large variety of goods are produced, of distinct size and design that all keep on changing as per the customer requirements. An example of an intermittent production system can be the work of a goldsmith. He does not produce goods (ornaments) on a continuous basis but on small scale as per the demand of customers. He is totally dependent upon the frequency of his customer’s order for carrying out its activities.

Intermittent Production system is composed of following types-

- Project Production Flows: It is one where a company accepts a company that undertakes a single complex contract that needs to complete at a budgeted cost and within the stipulated time period. Construction of roads, ships, dams, railways, airports etc. can be included in this type. All these products are not produced in large quantities by companies. It requires large efforts either in terms of money, labor, technology and several other resources for completing these contracts by business.

- Batch Production Flows: Under these types of production, the schedule of production is decided on the basis of demand forecasts or as per specific orders. Products are manufactured in large quantities in lots and stored safely till the time the demand arise. Whole product is divided into distinct jobs. A new production batch is started only once all jobs in previous production batch gets completed. This includes the manufacturing of heavy and medium machinery, drugs and pharmaceuticals etc.

- Jobbing Production Flows: Under the jobbing production flows, products are produced strictly in accordance to the customer specifications. Production is done at a fixed cost and within a certain period of time. Cost for a product is fixed when contract is sign by company. Repair shops, clothing workshops, special machine manufacturers etc. are examples of job production flows.

Continuous Production System

Continuous production system refers to one where all production activities move constantly without any frequent stops or irregularities. Here goods are produced continuously on a large scale for sale. There is no role of customer’s request in production activities and therefore the inputs and outputs are standardized together with process of production.

Continuous Production System includes the following types: –

- Mass Production Flows: Under the mass production flows, companies manufacture products in large scale and safely store them in warehouses till their demand arises in market. Either a single operation or a series of single operations are used for the production of products. Production of soaps, toothpaste, pens etc. are examples of mass production flows.

- Process Production Flows: In this only a single product is produced in a large scale and stored till their demand arises in market. Plants used here have nil flexibility as they are capable of producing only a single product. The well-known examples of this type are paper, sugar, cement, steel etc.