Contents

Meaning Logistics Management

Logistics Management is simply the movement of things in between the point of origin and point of final consumption. It is a term concerned with the formulation of plans, management, and implementation of processes related to the movement and storage of goods.

Logistics management is a process that strategically monitors the acquirement, storage, and movement of tangible items such as material, equipment, final goods, food, and consumable items, etc. Logistics management is an efficient tool widely used by business nowadays which handles all issues related to the procurement of materials, their handling and movement along the supply chain.

The managers who manage the whole complex process of logistics are termed as Logisticians. The process of logistics begins right from the moment when raw materials are acquired by the company and continue to the point of final delivery of the product to the user. The logistics management process focuses on reducing the expenses of the organization and improving service to customers by providing the right goods at right time.

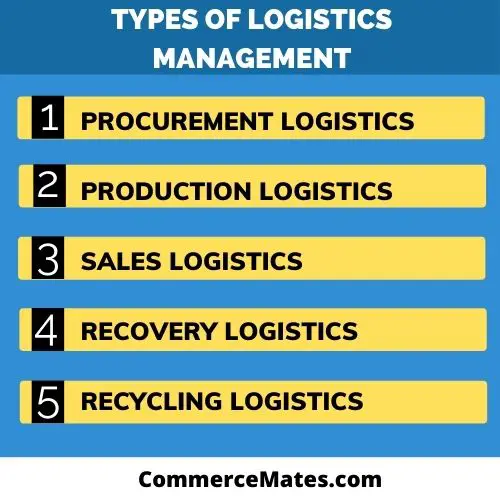

Types of Logistics Management

- Procurement Logistics: Procurement logistics is concerned with the procurement of raw materials and equipment needed for carrying out production activities. It is one which formulate plans, acquires, and coordinates various materials that are needed at a particular time and particular place for the production of goods. Procurement logistics include the storage of materials and moving them to the place where ever they are needed. It also examines the supply level at distinct stages of the production process to ensure that consumer needs are met timely.

- Production Logistics: Production logistics involves combining the various distributed supplies to form a product. It coordinates all activities together to create what is needed. This involves management of various operations like procuring parts, distributions within the organization, management of product, its packaging and dispatch to warehouse. It aims at optimizing the whole manufacturing process by proper coordination of all stages involved in production of goods. All materials are timely made available at place of work for creation of products.

- Sales Logistics: Sales logistics manages the operation related to movement of products from warehouse to wholesalers, retailer and consumer. It encompasses all those activities that ensure that goods reach the users at right time and at right place. Customer satisfaction is given due importance and attention is paid on delivering good in right form at low expenses.

- Recovery Logistics: Recovery logistics involves movement of goods in reverse order that is from end consumer back to the producer. It manages all activities related to movement of unused products that are not needed by customer or do not meet its requirements. Recovery logistics focuses on cost-efficient transportation of goods from consumption point to origin point for the motive of recovering value and proper disposal. Value is recapture through reuse, scrap recycling, rework and refurbishment.

- Recycling Logistics: Recycling statistics is concerned with recovering of recyclable products from customers for reusing them. It collects items such as empty cans, containers, used papers, empty plastic bottles, old computers, packing and ink cartridges. The role of recycling logistics is increasing nowadays as an effort to conserve environment by avoiding wastage via re-utilizing materials.

Nature and Scope of Logistics Management

- Network Design: Network Design is one of the prime function performed by process of logistic management. Logistic manager properly designs a network that denotes the number and location of production plants, storage houses, equipment for handling of materials etc. These factors are key determinants of efficiency of logistics and need to be decided with due attention.

- Procurement: Logistics management monitor the procurement of required materials and equipment for supporting manufacturing process of organization. It identifies supply sources, places order, manages inbound transportation, collect, inspect and store materials. All required raw materials of right quality are provided at right time at a minimum cost.

- Material Handling: Logistics management involves proper handling of all materials within organization like raw-materials, equipment’s, semi-finished and final goods. They need to be properly handled within and outside the manufacturing plant, storage house and transportation terminal. Managers need to ensure that there are no losses arising out of breakage, spoilage etc.

- Order Processing: Processing of consumer order is an important aspect of logistics management. It ensures that all order are timely processes and performs various operations like receiving, handling and recoding of consumer orders. Logistics management process focuses on reducing the time gap in between the order receipt and dispatch of consignment. It pays attention on fast processing of order and any delay in execution of order is avoided.

- Inventory Management: Logistics managers manages all the inventories of materials in right way. Proper amount of inventory is maintained at every point of time to facilitation uninterrupted production and regular supply of goods to consumers. Efforts are made to avoid any blockage of working capital in inventory. Overstocking and understocking of inventory is prevented and an optimum amount is always maintained.

- Packaging: Packaging and labelling are very important in logistics management. Packaging involves encasing products in proper packets for its safety and convenient handling. It makes product attractive and facilitate its sales. Labelling is a process of giving identification marks to product and defines its packaging and expiry date, ingredients, price, weight or size of product and instruction for proper handling.

- Warehousing: It is a logistical operation which aims at creating time utility by safe storage of products from the time in-between production point to consumption point. Logistic managers properly decide number and location of all warehouses to be established by company for proper storage of its products.

- Transportation: Transportation is a logistical activity which refers to movement of goods within and outside the organization. It creates time utility by delivering goods at right time and in right order. Railways, roadways, waterways, airways and pipeline are major sources of transportation used. Logisticians choose a right source of transportation by analyzing them in terms of their cost, speed, reliability, safety and no of its locations.

Objectives of Logistics Management

- Increased efficiency: Logistics management aims at increasing the overall efficiency of organization. It fastens all inbound and outbound logistics activities to accomplish the project within the stipulated time. Best quality materials are acquired at lowest possible cost and utilize efficiently with minimum wastage. Logistic managers monitor all operations and avoids any overheads which enhance the overall efficiency.

- Reliable and consistent delivery performance: Process of logistics management focuses on providing on-time delivery to customers for building their confidence level. Transport mode is selected through proper planning and required materials are transported rapidly to production plant for timely completion of project. Faster Delivery of goods at right place to consumer will enhance their satisfaction.

- Minimum product damage: Products damage adds cost to logistical expenses and have adverse effect on overall profitability. Logistic managers ensure that products are properly encased in suitable packages which impart them safety, properly handled and use of load unitization. Proper monitoring of all product movements by managers will minimize product damages.

- Reduce transportation cost: Logistic management process focuses on reducing the freight charges which bring down the logistical cost. Managers tries to lower the transportation expenses by choosing efficient transportation source, planning of shortest route, freight consolidation and load unitizing.

- Quick response: It reflects the capability of firms to serve its customers in proper manner timely. There should be a strong communication process which enables customers to easily give their orders and report their issues. Companies by implementing latest technology in information processing system will improve their decision making capability. It would make them flexible enough to fulfill their consumer needs in great volumes in proper time.

- Inventory reduction: Maintaining optimum inventory is must for smooth function of business. Logisticians aims at reducing the inventory level by rapidly processing all orders as excess inventory level leads to blockage of firm’s capital. Efforts are made to bring down the inventory level to minimum possible level by making frequent supplies, purchasing materials and producing products in an adequate amount.

Importance of Logistic Management

- Provide better service: Efficient logistic management enables in enhancing overall satisfaction level of customers. Logisticians formulate effective strategies and implement them to ensure that quality products are delivered timely by organization. Right management of logistics will enable company in fulfilling their customer requirements by providing them what they want.

- Ensure seamless Delivery: Process of logistic management has an efficient role in on-time delivery of products. It monitors all inbound and outbound movement of goods by selecting a team of professional members. Products are safely and rapidly shipped to deliver them at a right time, at right place and in right manner.

- Cost efficiency: Improving the overall efficiency of all activities is another important role played by logistic management. Logistician supervise each ongoing operation to ensure that all activities are going as per framed polices. Any deviations if there is identified and corrective measures are taken to reach optimum results. It is evaluated whether all resources are efficiently utilized and overhead costs are minimized which bring down the overall expenses.

- Order management: Logistic management facilitates speedy processing of consumer orders. It implements various technologies for information processing that led to accomplishment of project in adequate manner. Every order is properly managed form point of purchase up to final delivery point for improving the customer experience.

- Increase supply chain transparency: Logistics is an important tool of supply chain management which improve its overall transparency. It helps in easy tracking of every stage of supply chain ranging from production, warehousing, shipment to final delivery to user. Managers can easily get insight into what is going on or to what stage an order has processed. A reliable logistic system improves the image of business and boost its overall market value.